Plastics Dust Collection

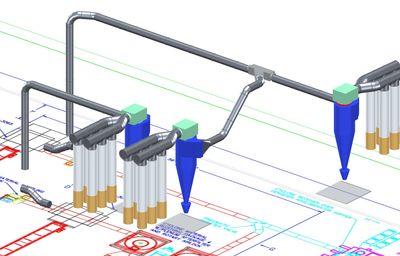

Dust Collection in a Plastic Application

Collecting and managing plastic dust is crucial in industrial settings where plastic processing or manufacturing takes place. Proper dust collection helps maintain a clean and safe work environment, minimizes the risk of respiratory issues, and prevents the accumulation of combustible dust that could pose a fire hazard. Here are some considerations for plastic dust collection:

1. Dust Collection System:

- Implement a dust collection system specifically designed for plastic dust. The system should include hoods, ductwork, and a collection unit that effectively captures and filters plastic dust.

2. Local Exhaust Ventilation (LEV):

- Use local exhaust ventilation systems, such as hoods or enclosures, positioned close to the source of plastic dust generation. This helps capture dust before it can disperse into the surrounding air.

3. Dust Collection Equipment:

- Select dust collectors with appropriate filters designed to capture fine plastic particles. Baghouse or cartridge filters are commonly used for this purpose.

4. Explosion Protection:

- Depending on the type of plastic being processed, there may be a risk of combustible dust. Consider explosion protection measures, such as explosion vents or suppression systems, to mitigate the risk of dust explosions.

5. Ductwork Design:

- Design the ductwork to minimize friction and static buildup, ensuring efficient transport of plastic dust to the collection unit. Always use smooth, anti-static duct materials.

6. Regular Maintenance:

- Implement a regular maintenance schedule for the dust collection system. This includes checking filters, cleaning ductwork, and ensuring that the collection unit is functioning optimally.

7. Dust Containment:

- Ensure that the dust collection system is properly sealed to prevent leaks and that the plastic dust is contained within the collection unit.

8. Dust Collection at Source:

- Whenever possible, collect plastic dust at the source to prevent it from dispersing into the general workspace. This may involve using hoods or enclosures directly at the machinery or processing equipment.

9. Airflow and Capture Velocity:

- Design the dust collection system to maintain adequate airflow and capture velocity for effective dust capture. This ensures that the plastic dust is drawn into the collection system efficiently.

10. Monitoring and Control:

- Implement monitoring systems to regularly assess the performance of the dust collection system. This may include pressure gauges to indicate filter conditions and airflow sensors to ensure proper capture velocities.

11. Worker Training and PPE:

- Train workers on the potential hazards of plastic dust and the importance of using personal protective equipment (PPE) such as respiratory protection in areas where dust exposure is possible.

12. Compliance with Regulations:

- Adhere to relevant workplace safety regulations and standards, including those set by organizations like the Occupational Safety and Health Administration (OSHA) in the United States.

It's important to tailor the plastic dust collection system to the specific processes and materials used in your facility. Consult with experts in industrial hygiene and dust collection to ensure that your system is designed and maintained for optimal safety and efficiency.

Exceptional Customer Service

I pride myself on providing exceptional customer service to all my clients. I am always ready to answer your questions, provide advice, and offer support whenever you need it.

Copyright © 2024 Industrial Solutions, llc - Dust Collection & Duct Work Expert - All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.